FARO Platinum Faro ArmThe Platinum FaroArm’s .001” accuracy renders traditional CMMs, hand tools and other portable inspection equipment obsolete. Anyone, anywhere can now inspect, reverse engineer or perform CAD-to-Part-analysis on parts, fixtures and assemblies with previously unheard of precision. When you partner that accuracy with its adaptable 3-D measurement technology (with or without CAD), it is ideal for forming, molding,fabricating, casting and assembly facilities. |

Most Common Applications

|

|

||

FARO Laser ScanArmThe first ever seven-axis contact/non-contact measurement device with a fully integrated FARO Laser Line Probe. Unlike other scanning systems, the ScanArm’s hard probe and Laser Line Probe can digitize interchangeably without having to remove either component. Users can accurately measure prismatic features with the arm’s hard probe, then laser scan sections requiring larger volumes of data (more than 19,000 points per-second) — without adding or removing attachments, untangling cabling, or having to use a separate CMM. |

Most Common Applications

|

|

||

FARO Laser TrackerThe FARO Laser Tracker is a portable, contact measurement system that uses laser technology to accurately measure large parts and machinery across a wide range of industrial applications. It has a 70m (230-ft.) diameter range, achieves 0.025mm (0.001”) 3-D single-point accuracy, and is rugged enough for the shop floor environment. |

Most Common Applications

|

|||

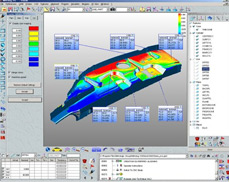

Metrolog XGMobile Measurement uses the latest in advanced 3D measurement software developed by the Metrologic group. Metrolog XG ® is a polyvalent 3D control software that fulfils today’s needs in terms of 3D measuring and quality control. It has been developed by a team rich of 20 years of experience and features state-of-the-art technologies for quality control. |

Features

|

|

||